Fast, flexible and efficient automated small-sparts warehouse

Our automatic small-parts warehouse for storing various sizes of containers and trays are available to you for different performance requirements.

These stacker cranes are automatically operated rail-mounted devices for automatic warehouses. These systems are designed for containers and trays weighing up to 50 kg.

The running gear and hoisting mechanism being constructed primarily of aluminium section, the storage and retrieval device only weighs about 2,000 kg.

We offer one-stop overall material flow solutions adapted to your processes, from the idea to a realised turnkey logistics System.

KTL 50

The basic unit for simple warehousing with standard containers up to a payload of 50 kg.

This stacker crane is the solution for simple warehousing or as an in-feed device for gravity picking systems.

Multiple load-lifting devices can be used to increase capacity.

KTL 250

The stacker crane for high storage capacities and loads up to 250 kg.

This stacker crane can be equipped with various load-lifting devices to meet the respective requirements.

Multiple load-lifting devices can be used to increase capacity.

Advantages of the system

- Mobility, functionality and economic efficiency for transporting packaging and for storage

- Fast and precise access to inventory, improvement of the overview of inventory and inventory security

- Speed when travelling: up to 6 m/s, and when lifting up to 2 m/s acceleration / deceleration to 2 m/s2

- Short approach dimensions

- Single- , double- or multiple-deep storage for increasing picking and inventory turnover performance

- Flexible load-carrying, carousel with up to 10 loading aids simultaneously

- Low overall weight

- Vulkollan track wheels make for less flexing work, lower energy requirement

- Frictional drive system, optimum efficiency, high energy efficiency

- All elements to be serviced are at the bottom of the device

Stabilo International GmbH, D-Weissenburg

Schwan-Stabilo is totally dedicated to the world of pens. Since its beginnings in the year 1865, the former Schwan-Bleistift-Fabrik (lead pencil factory) has grown into a globally successful corporate group which is the market leader for writing utensils in many countries.

Requirements

In mid-2008, the company began planning to expand and optimise the warehouse and order-picking systems in the distribution centre. This became necessary due to drastic changes in ordering behaviour, such as growth in fast-moving articles in small delivery lots.

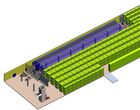

Logistics solution

Gilgen Logistics AG was commissioned to optimise the existing conveying and warehouse systems and to supply the new conveying system for containers and cardboard boxes including the control system, two automated small-part stacker cranes and the shelf system. Maintenance of all of these systems is also handled by Gilgen Logistics.

When designing the solution, care was taken to keep the routing arrangement (1,200 load carriers / hour) and interfloor connections for the conveying system as simple as possible. As a result, the smallest cardboard box (L/W/H: 225x155x215 mm with a weight of 100 g) can be transported on the conveying system without any transport aid.

The floors are interconnected by means of a paternoster lift. The order picking is executed via 340 picking channels, fed directly from the aisle of the small-part warehouse, and a two-level pick-by-light system.