Retrofitting and modernisation

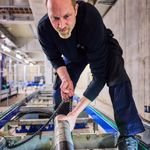

Preventive, tailored and professional.Retrofitting and modernisation – Fit for the future again

While technological progress is a significant driver of change, it is often process changes or capacity shortages that necessitate the renewal of a logistics system. Or signs of ageing:

- The system is technically obsolete.

- It is worn out.

- Its functions are outdated.

State-of-the-art technology

Even the best-designed systems and warehouses eventually become outdated. While the mechanics of older systems are often still in good condition, the control hardware, drive systems and sensors are no longer up to scratch. That is why modernisation efforts often focus on upgrading the control, measurement and drive technology.

Timely action saves money

Often, modernisation is delayed due to fears of production downtime or system failure. This makes it more susceptible to faults and thus less efficient. The optimisation potential in the workflow remains untapped for too long.

The benefits

By retrofitting your high-bay storage facility and conveyor system, you can enjoy the following benefits, depending on the features and the degree of modernisation:- Increased availability, reliability and uptime

- Lower operating costs

- Enhanced performance

- Adapted functionality to meet current requirements

- Compliance with safety regulations

- Greater ease of use and improved visualisation

- Improved networking and remote diagnostics

- Guaranteed availability of spare parts

Our core competencies

To provide you with the competitive edge you need, we focus on the following core competencies in our retrofitting services:- Consulting, planning and engineering

- Mechanical adjustments and new developments

- Adjustments to control hardware/software and warehouse management systems

- Installation and integration of new or existing system components

- Coordination with other departments

- We can also modernise systems of other providers.

References