Spiralift

Spiralift – the future of lift technology

The story of Spiralift technology began in the early 1980s and is one of progress and innovation.When the PACO Group entered the stage machinery business, its leaders had no idea they were about to revolutionise the world of lifting technology. In 1988, they faced a challenge that would change everything: building an orchestra lift in Davis, California.

Necessity is the mother of invention

The engineers faced an obstacle that seemed insurmountable at the time: the space for the machine pit was too small, and traditional lifting mechanisms simply wouldn’t fit. But from this challenge, something groundbreaking was born.

Pierre Gagnon and Pierre Laforest, key figures at the company, gave their creativity free rein. After a weekend of brainstorming, Laforest unveiled a revolutionary solution on the Monday morning: the first rough steel-band prototype of Spiralift. This milestone not only transformed stage lift systems in the entertainment industry, but also established Spiralift technology as the new benchmark for lifting solutions.

The ingenious engineering behind Spiralift

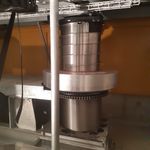

Spiralift technology combines vertical and horizontal stainless steel bands in an ingenious design, creating a stable and robust lift column capable of handling loads safely and efficiently.At the heart of this system is a cylindrical rotor with a screw-like mechanism. As the rotor turns, it lifts the horizontal band while simultaneously layering the vertical band over it, causing both bands to interlock. The result is a reliable lift column in which the bands are precisely synchronised to deliver optimum performance.

Highly precise and stable

The screw-like mechanism stabilises and controls the movement of the column, ensuring a high level of precision and stability. This allows Spiralift technology to lift and lower loads with impressive accuracy and safety.

Highly versatile

Spiralift technology is a true feat of engineering that combines precision, stability and durability in a compact and efficient design. With its outstanding performance and versatility, it offers the ideal solution for a wide range of lifting projects across various industries.

Why Spiralift technology?

Spiralift technology has proved itself worldwide and is used in some of the most advanced production facilities.Over 60 per cent of automotive manufacturers rely on its robust and stable lift column, which requires only very little space. But what makes this technology so unique?

Compact design

Spiralift technology delivers maximum performance with a minimal footprint, making it suitable for any environment, but especially ones in which space is limited. It adapts to spatial limitations yet still offers impressive lifting capacity.

Energy efficiency

The intelligent Spiralift design reduces energy consumption, which not only benefits the environment, but also keeps your operating costs low.

Easy integration

The plug-and-play functionality allows for quick and seamless integration into existing systems and production environments. This saves you time and money while also boosting efficiency.

Robust and low-maintenance

Reliability is our second name. That’s why we have designed Spiralift technology for long-term use with minimal maintenance. It is built to withstand even the most demanding conditions while consistently delivering top performance over long periods.

Highly versatile

From automotive manufacturing to stage technology, the versatile Spiralift system offers a solution to almost any challenge.

Are you ready to experience the future of lifting technology? With Spiralift, you can be confident that your lifting projects will run smoothly and efficiently. Discover the power and versatility of this innovative technology.