Kägi, CH-Lichtensteig

Pallet lift over 3 storeysSince 1934, the company from Lichtensteig in the canton of St. Gallen has been making the world's biscuit lovers a little happier. Kägi biscuits and wafers have long since become an export hit and are now sold in over 30 countries. A recipe from Gilgen was needed to make production in Lichtensteig more efficient.

Problem

"Efficiency brake" goods liftThe production of Kägi creations extends over three floors. Previously, the goods had to be transported from floor to floor by employees using goods lifts - a time-consuming and labour-intensive process step.

Solution

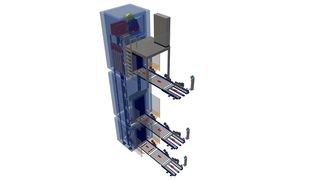

Automatic pallet liftWe have installed an automatic pallet lift for Kägi production. This means that employees only have to guide the pallets onto the floor-level conveyor sections using a hand pallet truck and select the destination floor on the control panel. The visualised control system makes operation and troubleshooting particularly easy. The access points to the lift shaft are secured with sliding doors, which also serve as fire protection.

Benefits

Speed and reliabilityVertical pallet transfers are now quick and reliable at Kägi and require only a small number of personnel.

Thanks to the pallet lift, our employees can now concentrate fully on what really matters: top product quality.

Hanspeter Scherrer, project manager Kägi

More References

Food Industry